Turn efficiency into a competitive edge with the MGPRO® ecosystem

Turn efficiency into a competitive edge with the MGPRO® ecosystem

Optimise resources and maximise results

The MGPRO® ecosystem is an integrated solution that combines Management Consulting (OEE+) and Information Technology (MGPRO® Platform) to take your factory to the next level. Developed to meet the growing demands of Industry 4.0, it goes beyond automation by strategically aligning processes, information and people. This holistic approach boosts operational efficiency and equips companies for the challenges ahead.

Processes, Information and People

Drawing on seminal works such as Lean Thinking by James P. Womack and Daniel T. Jones, and The Toyota Way by Jeffrey K. Liker, the three fundamental pillars—Processes, Information and People—form the essential framework for achieving excellence in operational efficiency. This holistic approach weaves together technology, processes and people, fostering an organisational environment that turns challenges into outstanding results.

Processes

Transforming Resources into Results

Processes represent the flow of activities that turn resources into finished products. This pillar spans every stage of the value chain, ensuring efficiency and quality from the intake of raw materials to final delivery to the customer. Key areas include:

Production and logistics

Maintenance and quality

Integrated operations management

Information

Data-driven decisions

Information is the bedrock of precise, agile decision-making. This pillar covers the technological tools and infrastructures that allow organisations to monitor, analyse and act efficiently. Key elements include:

Information systems, automation and IoT

Indicator dashboards

Data-driven actions

People

The central pillar of transformation

No operational improvement programme succeeds without the active involvement of people. They are the heart of execution, control and decision-making that affects every process. To unlock the full potential of this pillar, focus on:

Training and upskilling

Organisational culture

Engagement and motivation

Effective communication

Change programmes to maximise your factory’s efficiency

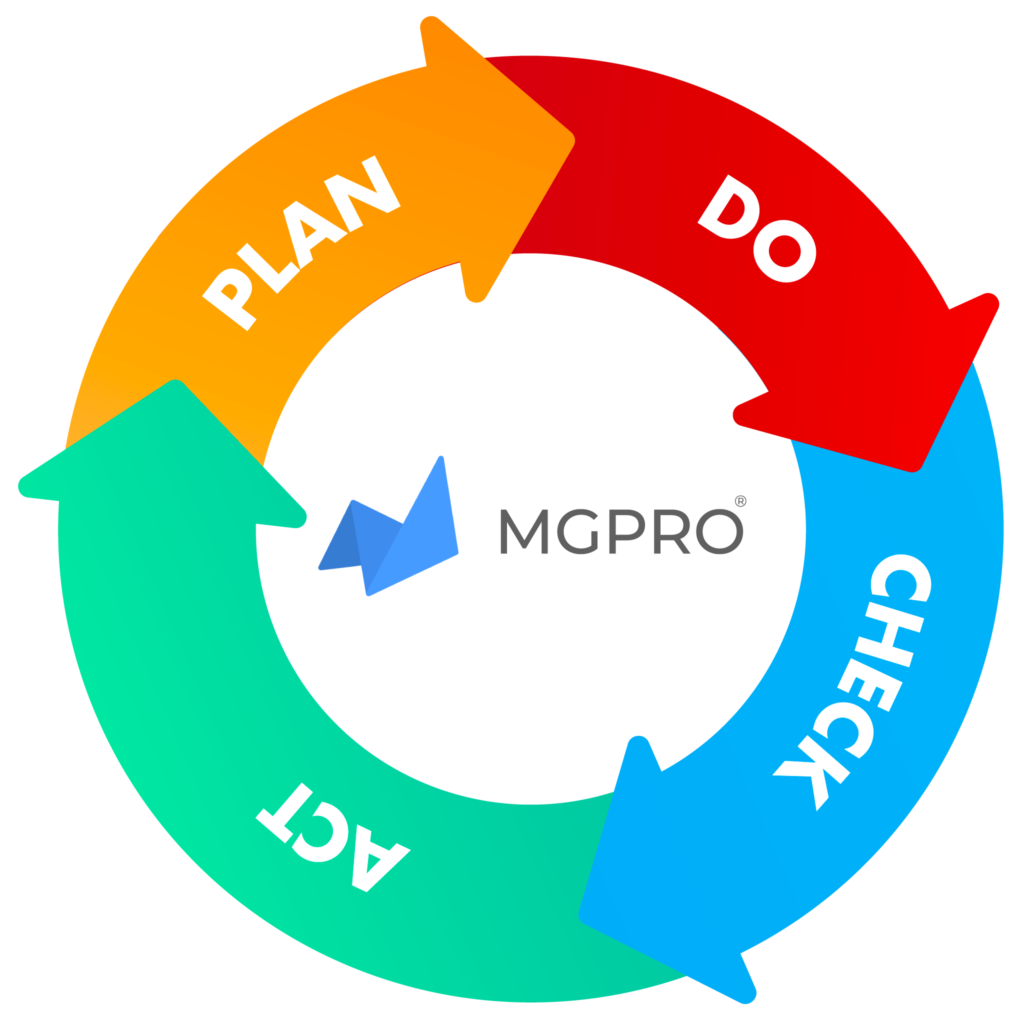

OEE+ is a strategic suite of programmes designed to transform your company’s management. It identifies, quantifies and addresses opportunities, ensuring your operations achieve the best possible results.

Programmes to optimise operations

The programmes are based on leading operational-efficiency methodologies and include:

SMED (Single-Minute Exchange of Die – change-over time reduction)

5S (organisation and standardisation)

Preventive and Autonomous Maintenance

Kaizen (continuous improvement)

Management and monitoring tools

They also cover the review, alignment and implementation of indicators and systems for tighter control, such as:

MES (Manufacturing Execution System)

ERP (Enterprise Resource Planning)

Performance-indicator dashboards

Training to sustain change

Empowering your team is essential for consolidating efficient, innovative management. The training programmes focus on:

Using control and management tools

Fostering a culture of continuous improvement

Effective communication

Engagement and motivation

A solution far beyond MES

The MGPRO® Platform is more than a technological solution—it is a strategic tool designed to revolutionise industrial management. Its mission is to boost operational efficiency by delivering precise, real-time information, enabling swift and decisive decision-making.

Production scheduling

Performance

Process control

Continuous improvement

Simple installation

Make the most of our expertise in data collection and management.

• Installation support

• Master data

• Custom implementation

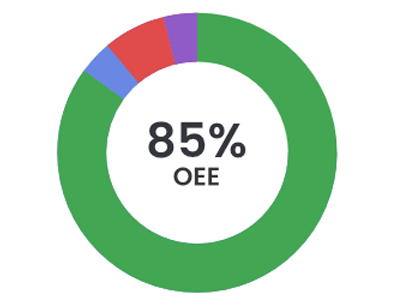

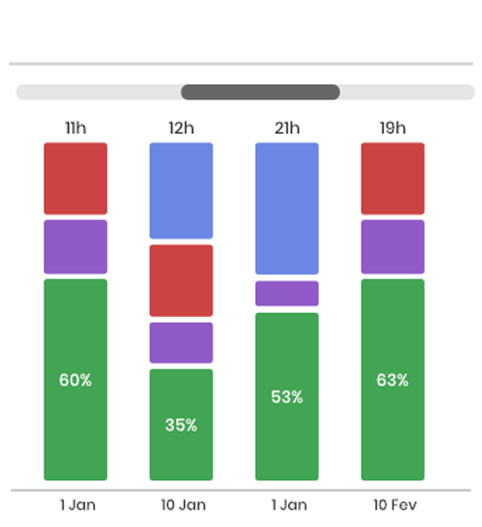

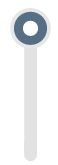

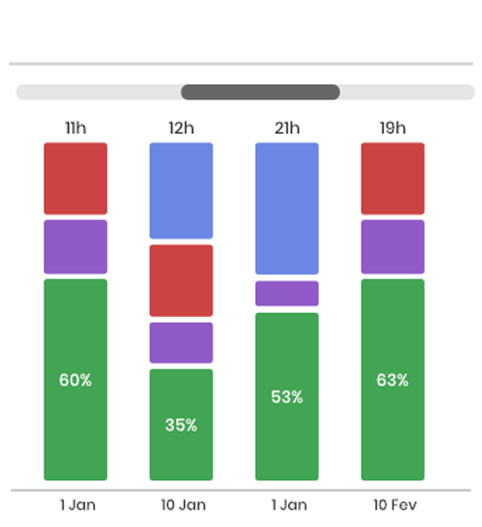

Performance

Monitor your equipment’s efficiency in real time and pinpoint the causes of downtime and waste.

OEE •Downtime •Waste •Volumes

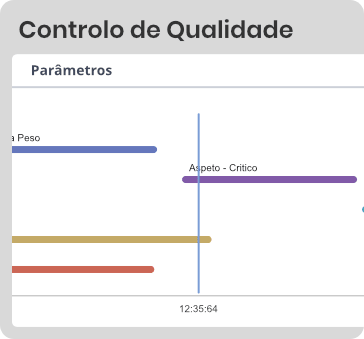

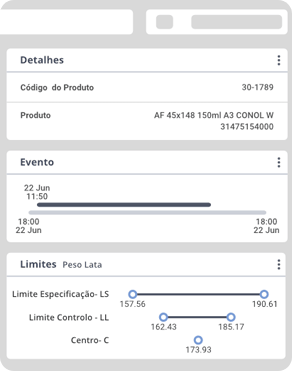

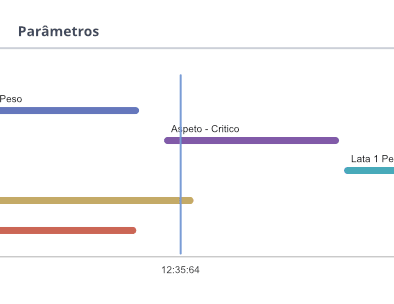

Statistical process control

Keep quality within specification limits by tracking deviations in your production process.

Specifications •Parameters •Events

Reports

Beyond daily production and quality reports, analyse trends and compare periods, crews, shifts, products and much more…

• Performance

• Quality

• Trends

Continuous improvement

Act to minimise deviations from targets. With our Continuous Improvement Module, manage and take part in problem-solving.

• Problems

• Solutions

• Deadlines

• Owners

And much more!

ERP integration Multi-platform Corporate overview